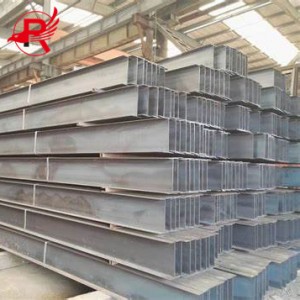

ASTM H-formet stål H-bjælke | Varmvalset H-bjælke til stålsøjler og -profiler

ASTM A36 H-bjælkeer en type stålbjælke fremstillet af kulstofstål, et udbredt og alsidigt materiale kendt for sin høje styrke og holdbarhed. H-bjælker er kendetegnet ved deres karakteristiske "H"-form, som giver fremragende bæreevne og støtte i forskellige bygge- og ingeniørapplikationer. Med sine overlegne strukturelle egenskaber anvendes H-bjælker af kulstofstål almindeligvis i konstruktionen af bygninger, broer og andre infrastrukturprojekter. Det tilbyder en økonomisk og pålidelig løsning til at skabe robuste og elastiske rammeværker, hvilket gør det til et populært valg i byggebranchen. Kulstofstålets iboende styrke og svejsbarhed forbedrer yderligere dets egnethed til tunge strukturelle applikationer, hvilket gør H-bjælker til et foretrukket valg for ingeniører og bygherrer, der søger pålidelige og effektive byggematerialer.

Detaljerne for en varmvalset stål H-bjælke omfatter typisk følgende specifikationer:

Dimensioner: H-bjælkens størrelse og dimensioner, såsom længde, bredde og tykkelse, specificeres i henhold til projektets krav.

Tværsnitsegenskaber: Nøgleegenskaber for H-bjælken omfatter areal, inertimoment, tværsnitsmodul og vægt pr. længdeenhed. Disse egenskaber er afgørende for beregning af pælens strukturelle design og stabilitet.

PRODUKTPROCESSEN

1. Forberedelse: inklusive indkøb af råmaterialer, kvalitetskontrol og materialeforberedelse. Råmaterialet er normalt smeltet jern produceret fra stålfremstilling i grafitiseringsovne af høj kvalitet eller stålfremstilling i elektriske ovne, som sættes i produktion efter kvalitetskontrol.

2. Smeltning: Hæld det smeltede jern i konverteren, og tilsæt passende returstål eller svinejern til stålfremstilling. Under stålfremstillingsprocessen kontrolleres kulstofindholdet og temperaturen i det smeltede stål ved at justere doseringen af grafitiseringsmiddel og blæse ilt ind i ovnen.

3. Stålfremstillingsbarrer: Stålfremstillingsbarren hældes i støbemaskinen, og det strømmende vand fra støbemaskinen sprøjtes ind i krystallisatoren, så det smeltede stål gradvist størkner og danner en barre.

4. Varmvalsning: Den kontinuerlige støbeemne varmvalses gennem varmvalsningsenheden for at opnå den angivne størrelse og geometriske form.

5. Færdigvalsning: Den varmvalsede barre færdigvalses, og barrens størrelse og form gøres mere præcis ved at justere valseværkets parametre og styre valsekraften.

6. Afkøling: Det færdige stål afkøles for at reducere temperaturen og fiksere dimensioner og egenskaber.

7. Kvalitetskontrol og emballering: Kvalitetskontrol af færdige produkter og emballering i henhold til størrelses- og mængdekrav.

PRODUKTSSTØRRELSE

| Produkter | Varmvalset H-bjælke |

| Oprindelsessted | Hebei, Kina |

| Grad | Q235B/SS400/Q355B/S235JR/S355JR |

| Standard | ASTM / AISI / JIS / EN / DIN |

| Størrelse | Netbredde: 100-912 mm |

| Flangebredde: 50-302 mm | |

| Nettykkelse: 5-18 mm | |

| Flangetykkelse: 7-34 mm | |

| Legering eller ej | Ikke-legeret |

| Teknisk | kold- eller varmvalset |

| Behandlingstjeneste | Bukning, svejsning, stansning, skæring |

| Leveringstid | 31-45 dage |

| Længde | 1-12m |

| Fakturering | efter teoretisk vægt |

| Anvendelse | bygningsstruktur og ingeniørstruktur |

| Betaling | T/T; |

| H-bjælkestørrelse | ||||

| Netbredde (mm) | Flangebredde (mm) | Nettykkelse (mm) | Flangetykkelse (mm) | Teoretisk vægt (kg/m²) |

| 100 | 50 | 5 | 7 | 9,54 |

| 100 | 100 | 6 | 8 | 17.2 |

| 125 | 60 | 6 | 8 | 13.3 |

| 125 | 125 | 6,5 | 9 | 23,8 |

| 150 | 75 | 5 | 7 | 14.3 |

| 148 | 100 | 6 | 9 | 21.4 |

| 150 | 150 | 7 | 10 | 31,9 |

| 175 | 90 | 5 | 8 | 18.2 |

| 175 | 175 | 7,5 | 11 | 40,4 |

| 194 | 150 | 6 | 9 | 31.2 |

| 198 | 99 | 4,5 | 7 | 18,5 |

| 200 | 100 | 5,5 | 8 | 21,7 |

| 200 | 200 | 8 | 12 | 50,5 |

| 200 | 204 | 12 | 12 | 56,7 |

| 244 | 175 | 7 | 11 | 44,1 |

| 248 | 124 | 5 | 8 | 25,8 |

| 250 | 125 | 6 | 9 | 29,7 |

| 250 | 250 | 9 | 14 | 72,4 |

| 250 | 255 | 14 | 14 | 82,2 |

| 294 | 200 | 8 | 12 | 57,3 |

| 294 | 302 | 12 | 12 | 85 |

| 298 | 149 | 5,5 | 8 | 32,6 |

| 300 | 150 | 6,5 | 9 | 37,3 |

| 300 | 300 | 10 | 15 | 94,5 |

| 300 | 305 | 15 | 15 | 106 |

| 340 | 250 | 9 | 14 | 79,7 |

| 344 | 348 | 10 | 16 | 115 |

| 346 | 174 | 6 | 9 | 41,8 |

| 350 | 175 | 7 | 11 | 50 |

| 350 | 350 | 12 | 19 | 137 |

| 388 | 402 | 15 | 15 | 141 |

| 390 | 300 | 10 | 16 | 107 |

| 394 | 398 | 11 | 18 | 147 |

| 396 | 199 | 7 | 11 | 56,7 |

| 400 | 200 | 8 | 13 | 66 |

| 400 | 400 | 13 | 21 | 172 |

| 400 | 408 | 21 | 21 | 197 |

| 414 | 405 | 18 | 28 | 233 |

| 428 | 407 | 20 | 35 | 284 |

| 440 | 300 | 11 | 18 | 124 |

| 446 | 199 | 8 | 12 | 66,7 |

| 450 | 200 | 9 | 14 | 76,5 |

| 458 | 417 | 30 | 50 | 415 |

| 482 | 300 | 11 | 15 | 115 |

| 488 | 300 | 11 | 18 | 129 |

| 496 | 199 | 9 | 14 | 79,5 |

| 498 | 432 | 45 | 70 | 605 |

| 500 | 200 | 10 | 16 | 89,6 |

| 506 | 201 | 11 | 19 | 103 |

| 582 | 300 | 12 | 17 | 137 |

| 588 | 300 | 12 | 20 | 151 |

| 594 | 302 | 14 | 23 | 175 |

| 596 | 199 | 10 | 15 | 95,1 |

| 600 | 200 | 11 | 17 | 106 |

| 606 | 201 | 12 | 20 | 120 |

| 692 | 300 | 13 | 20 | 166 |

| 700 | 300 | 12 | 24 | 185 |

| 792 | 300 | 14 | 22 | 191 |

| 800 | 300 | 14 | 26 | 210 |

| 890 | 299 | 15 | 23 | 213 |

| 900 | 300 | 16 | 28 | 243 |

| 912 | 302 | 18 | 34 | 286 |

FORDEL

Nogle funktioner og karakteristika ved kulstofstålASTM A370 H-bjælke:

- Stærkt og holdbart: Kulstofstål er kendt for sin høje styrke og holdbarhed, hvilket gør H-bjælker i stand til at bære tunge belastninger og give strukturel stabilitet.

- Alsidig: H-bjælker lavet af kulstofstål er alsidige og kan bruges i en bred vifte af byggeprojekter, herunder bygningsrammer, broer og andre strukturer.

- Effektiv bæreevne: Bjælkens unikke H-form giver effektiv bæreevne, hvilket gør den velegnet til at understøtte forskellige typer strukturer.

- Økonomisk:ASTM A572 H-bjælketilbyde en omkostningseffektiv løsning til bygge- og anlægsprojekter på grund af materialets tilgængelighed og overkommelige priser.

- Svejsbar: Kulstofstål kan let svejses, hvilket muliggør fremstilling af tilpassede H-bjælker, der opfylder specifikke projektkrav.

PROJEKT

Vores virksomhed har mange års erfaring med udenrigshandel med H-bjælker. Den samlede mængde H-bjælker, der eksporteres til Canada denne gang, er mere end 8.000.000 tons. Kunden vil inspicere varerne på fabrikken. Når varerne har bestået inspektionen, vil betalingen blive foretaget og afsendt. Siden opførelsen af dette projekt startede, har vores virksomhed omhyggeligt arrangeret produktionsplanen og udarbejdet procesflowet for at sikre rettidig levering af H-formede stålprojekter. Da det bruges i store fabriksbygninger, er ydeevnekravene til H-formede stålprodukter højere end korrosionsbestandigheden for H-formede stålprodukter fra olieplatforme. Derfor starter vores virksomhed fra produktionskilden og øger kontrollen over stålfremstilling, kontinuerlig støbning og valsningsrelaterede processer. Styrker kvaliteten af produkter med forskellige specifikationer for at kontrollere dem effektivt i alle aspekter og sikrer en 100% beståelsesrate for færdige produkter. I sidste ende blev forarbejdningskvaliteten af H-formede stål enstemmigt anerkendt af kunderne, og et langsigtet samarbejde og gensidig fordel blev opnået på grundlag af gensidig tillid.

PRODUKTINSPEKTION

For almindeligeASTM A6 H-bjælkeHvis kulstofindholdet er 0,4 % til 0,7 %, og kravene til de mekaniske egenskaber ikke er særlig høje, kan normalisering anvendes som den endelige varmebehandling. Først skal der produceres krydsformede stålsøjler. Efter arbejdsdeling på fabrikken samles, kalibreres og inspiceres de for at sikre, at produkterne er kvalificerede, og de transporteres derefter til byggepladsen til splejsning. Under splejsningsprocessen skal splejsningen udføres i nøje overensstemmelse med de tilsvarende procedurer. Kun på denne måde kan produktets kvalitet effektivt garanteres. Når samlingen er afsluttet, skal de endelige installationsresultater inspiceres. Efter inspektionen skal ultralydbølger anvendes til at udføre ikke-destruktiv inspektion af det indre, så defekter forårsaget under samlingen effektivt kan elimineres. Derudover kræves der også krydssøjlebehandling. Under installationen af stålkonstruktionen skal du først vælge standardannotationen, lukke nettet for kontrol og derefter udføre en lodret måling af søjlens tophøjde. Derefter skal forskydningen af søjletoppen og stålkonstruktionen bearbejdes for superudbøjning, og derefter skal resultaterne af superfladen og inspektionsresultaterne af den nederste søjle behandles grundigt. Bearbejdningen af tykke fødder skal udføres, efter at stålsøjlens position er bestemt. Gennem analyse af bearbejdningsdataene korrigeres stålsøjlens vertikalitet igen. Efter installationen er afsluttet, skal måleregistreringerne gennemgås, og svejseproblemerne skal inspiceres. Derudover skal lukningen af kontrolpunkterne inspiceres igen. Endelig skal præ-kontroldatadiagrammet for den nederste stålsøjle tegnes.

ANVENDELSE

H-bjælker i stålkonstruktioner anvendes almindeligvis i en række forskellige bygge- og ingeniørmæssige applikationer på grund af deres styrke, alsidighed og bæreevne. Nogle almindelige anvendelser af H-bjælker i stålkonstruktioner inkluderer:

1. Bygningskonstruktion: H-bjælker bruges ofte som strukturelle understøtninger i bygningskonstruktioner, herunder til søjler, bjælker og tagstøtter. De giver en robust ramme til både erhvervs- og boligstrukturer.

2. Brokonstruktion: H-bjælker er afgørende komponenter i bygning af broer, hvor de bruges til at bære brodækkets vægt og lette fordelingen af laster på tværs af konstruktionen.

3. Industrielle strukturer: H-bjælker spiller en nøglerolle i at understøtte tungt udstyr, maskiner og infrastruktur i industrielle faciliteter såsom produktionsanlæg, lagre og distributionscentre.

4. Infrastrukturprojekter: H-bjælker i stålkonstruktioner anvendes i konstruktionen af infrastrukturprojekter såsom motorveje, jernbaner og tunneler, hvor deres bæreevne er afgørende for at understøtte store spændvidder og tunge belastninger.

5. Støttemure og pæle: H-bjælker bruges som fundamentale elementer i støttemure og pælesystemer, hvor de giver strukturel stabilitet og støtte til jordfastholdelse og stabilisering.

6. Arkitektoniske anvendelser: Ud over deres strukturelle anvendelser anvendes H-bjælker også i arkitektoniske designs til at skabe karakteristiske visuelle elementer, såsom synlige bjælker og æstetiske træk i moderne byggeri.

EMBALLAGE OG FORSENDELSE

Emballage:

Stabl spunsvæggene sikkert: ArrangerASTM A992 H-bjælkei en pæn og stabil stak, og sørg for at de er korrekt justeret for at forhindre ustabilitet. Brug stropper eller bånd til at fastgøre stakken og forhindre forskydning under transport.

Brug beskyttende emballagematerialer: Pak spunsvæggene ind i et fugtbestandigt materiale, såsom plastik eller vandtæt papir, for at beskytte dem mod vand, fugtighed og andre miljømæssige elementer. Dette vil hjælpe med at forhindre rust og korrosion.

Forsendelse:

Vælg en passende transportform: Afhængigt af mængden og vægten af spunsvæggene skal du vælge den passende transportform, såsom fladvogne, containere eller skibe. Overvej faktorer som afstand, tid, omkostninger og eventuelle lovkrav til transport.

Brug passende løfteudstyr: Brug passende løfteudstyr såsom kraner, gaffeltrucks eller læssere til at laste og losse de U-formede stålspunsvægge. Sørg for, at det anvendte udstyr har tilstrækkelig kapacitet til at håndtere spunsvæggenes vægt sikkert.

Fastgør lasten: Fastgør den pakkede stak af spunsvægge korrekt på transportkøretøjet ved hjælp af stropper, afstivning eller andre egnede midler for at forhindre forskydning, glidning eller fald under transport.

VIRKSOMHEDENS STYRKE

Lavet i Kina, førsteklasses service, banebrydende kvalitet, verdenskendt

1. Skalaeffekt: Vores virksomhed har en stor forsyningskæde og en stor stålfabrik, der opnår skalaeffekter inden for transport og indkøb og er blevet en stålvirksomhed, der integrerer produktion og service.

2. Produktdiversitet: Produktdiversitet, ethvert stål du ønsker kan købes hos os. Vi beskæftiger os primært med stålkonstruktioner, stålskinner, stålspunsvægge, solcellebeslag, kanalstål, siliciumstålspoler og andre produkter, hvilket gør det mere fleksibelt. Vælg den ønskede produkttype for at imødekomme forskellige behov.

3. Stabil forsyning: En mere stabil produktionslinje og forsyningskæde kan give en mere pålidelig forsyning. Dette er især vigtigt for købere, der har brug for store mængder stål.

4. Brandindflydelse: Har større brandindflydelse og et større marked

5. Service: En stor stålvirksomhed, der integrerer tilpasning, transport og produktion

6. Priskonkurrenceevne: rimelig pris

*Send e-mailen til[email protected]for at få et tilbud på dine projekter

Ofte stillede spørgsmål

1. Hvordan kan jeg få et tilbud fra dig?

Du kan efterlade en besked, og vi vil besvare alle beskeder til tiden.

2. Vil du levere varerne til tiden?

Ja, vi lover at levere produkter af den bedste kvalitet og levering til tiden. Ærlighed er vores virksomheds princip.

3. Kan jeg få prøver før bestilling?

Ja, selvfølgelig. Normalt er vores prøver gratis, og vi kan producere dem ud fra dine prøver eller tekniske tegninger.

4. Hvad er dine betalingsbetingelser?

Vores sædvanlige betalingsbetingelse er 30% depositum, og resten betales mod B/L.

5. Accepterer du tredjepartsinspektion?

Ja, det accepterer vi absolut.

6. Hvordan stoler vi på jeres virksomhed?

Vi har specialiseret os i stålbranchen i årevis som guldleverandør, med hovedkontor i Tianjin-provinsen. Vi er velkomne til at undersøge sagen på alle måder.